HOW TO DO A

SUSTAINABLE

PRODUCTION

CHAIN

CORPORATE

YOUR COMPANY

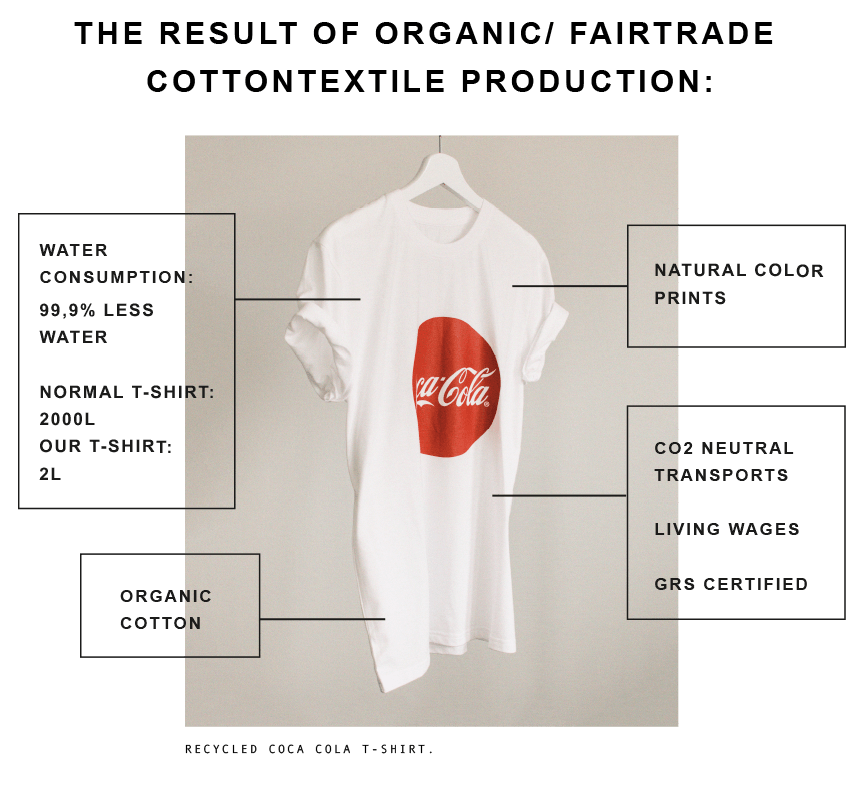

In addition to certifications like GOTS, GRS and Living wages as well as collaborations with Zero Mission and Fairtrade, we have chosen to focus on reuse and natural circuits where everything is used and as little as possible will be wasted.

Closing the loop. There are a number of ways to avoid water waste. One of our biggest factories receives up to 95% of their water from monsoon rain and the dying process is carried out in a closed-loop purification system using treatment ponds, sand filtration and reverse osmosis, converting waste water into clean water using solar power.

Transparency. By working with manufacturers on-site in factories, we can choose the right production- and manufacturing methods at an early stage without deteriorating the conditions of those working there. A deeper partnership and presence locally enable transparency and also leads to errors can be adjusted at an early stage, which in turn increases delivery security.

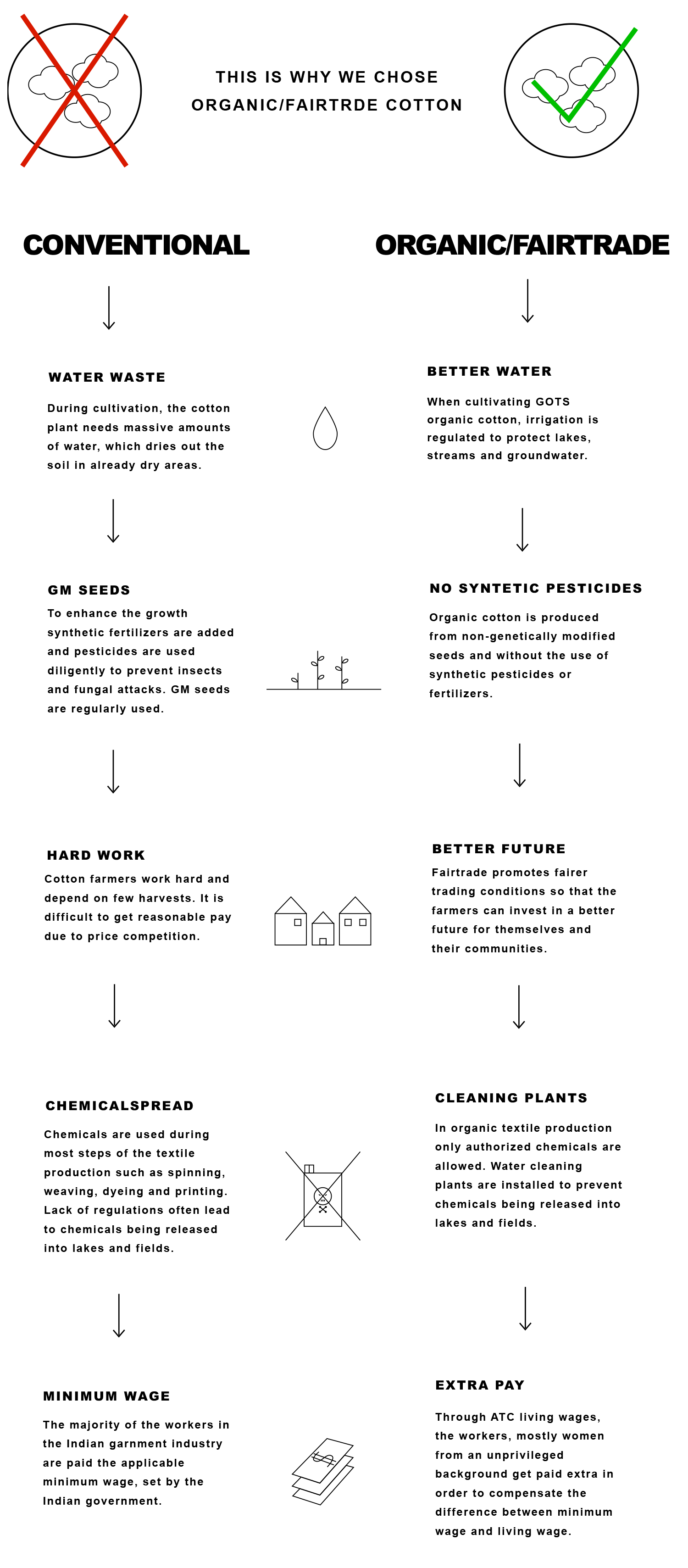

CONVENTIONAL

VS.

ORGANIC/

FAIRTRADE

COTTON TEXTILE PRODUCTION IN INDIA